DTC: Your Trusted Factory Construction Company in Dammam

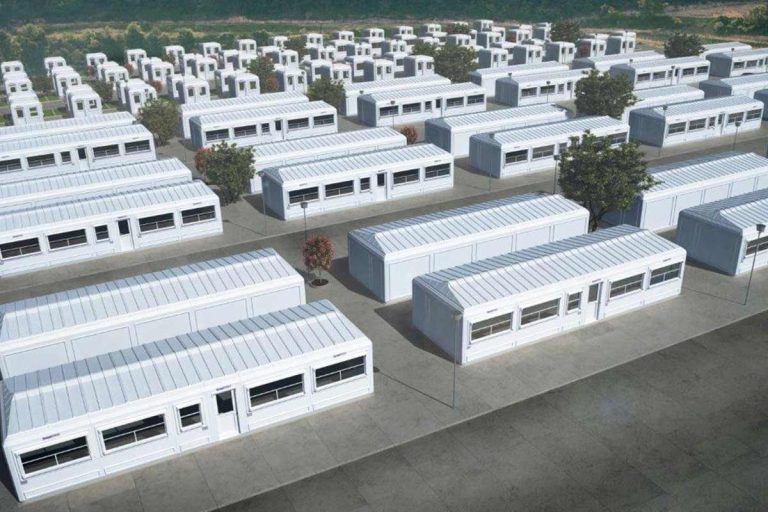

If you’re searching for a factory construction company in Dammam with the expertise to handle large-scale industrial projects, DTC General Contracting stands out as a top choice. One of the best examples of DTC’s industrial prowess is the Al Yamamah Steel Factory, located in the heart of Dammam Industrial City. This ambitious project underscores DTC’s commitment to building high-quality, technologically advanced, and sustainable industrial facilities that meet the rigorous demands of Saudi Arabia’s growing industrial sector.

Below, we’ll dive into the features, systems, and innovative design elements that make Al Yamamah Steel Factory a prime example of DTC’s dedication to excellence. We’ll also explore why DTC is the go-to name for constructing robust factories in the Eastern Province—and how their forward-thinking approach to safety, sustainability, and technology can benefit your next project.

Al Yamamah Steel Factory: A Benchmark for Industrial Construction

Modern Steel Production in Dammam

The Al Yamamah Steel Factory is strategically situated in Dammam Industrial City, leveraging the city’s established infrastructure and convenient access to major transport routes. This prime location not only ensures seamless logistics but also positions the factory to serve customers quickly and efficiently. By integrating state-of-the-art machinery, efficient workflows, and green building practices, DTC has created a facility that aligns with the broader vision of industrial growth in Saudi Arabia.

Key Project Highlights

- Cutting-Edge Machinery and Infrastructure

Al Yamamah Steel Factory is outfitted with advanced machinery to facilitate large-scale steel manufacturing and processing. From powerful rolling mills and automated feeding systems to intricate cutting lines, each piece of equipment is strategically placed to boost production capabilities while maintaining safe operating conditions. - Efficient Workflow and Scalability

DTC designed the layout of the production building to optimize workflow. Raw materials flow in from one side, pass through production lines with minimal manual handling, and exit as finished products at the other end. This streamlined approach not only reduces downtime but also allows for future expansions, such as new production lines or storage areas, without major structural overhauls. - Integrated Administrative Building

A well-equipped administrative building supports the factory’s management and operational staff. Modern offices, meeting rooms, and recreational areas foster efficient communication between departments—ensuring that production teams can work hand-in-hand with logistics, finance, and human resources. - State-of-the-Art Warehouses

Warehouses attached to the facility securely store raw materials like steel billets and coils, as well as finished steel products ready for distribution. Each warehouse space is designed with durable flooring, ample lighting, and straightforward access routes, enabling smooth inbound and outbound operations.

Key Systems and Infrastructure

Power Distribution Network

A stable and efficient power supply is critical in steel manufacturing. DTC implemented a robust power distribution network that guarantees uninterrupted electricity to every corner of the factory. Such reliability is indispensable given that downtime can translate into significant financial losses and production bottlenecks.

Lighting System

Bright, consistent lighting can improve both safety and productivity. The factory’s lighting system relies on advanced fixtures—often LED-based—tailored for industrial settings. These lights minimize glare and heat, creating a comfortable and secure work environment, even in round-the-clock operations.

Low Current System

Modern industrial facilities demand more than just machinery; they need integrated digital solutions. The Al Yamamah Steel Factory includes a low current system featuring:

- Building Management System (BMS) to monitor and control facility conditions

- Fire Alarm (FA) and CCTV for real-time safety and security

- Data networking solutions that keep teams connected

Complete Firefighting & Alarm System

In an environment handling high-temperature processes and flammable materials, safety is paramount. DTC installed specialized firefighting systems—like FM-200 & CO2 solutions and a deluge foam system—to address different fire risks throughout the production area. Additionally, the fire alarm network integrates with emergency protocols, ensuring rapid response in critical situations.

Utilities Work and HVAC

Factories can be demanding in terms of utilities:

- Plumbing and Drainage Network: Resilient systems handle industrial discharge without compromising hygiene and environmental standards.

- Compressed Air Piping and Equipment: Many production lines rely on pneumatic tools and automation, requiring a stable air supply.

- Chilled Water System with Air Handling Units (AHUs) & Fan Coil Units (FCUs): An advanced HVAC system controls the internal climate, crucial for both workforce well-being and process stability.

Construction and Installation of Prefabricated Steel Structures

DTC leverages prefabricated steel structures to expedite construction schedules and enhance structural resilience. Prefabrication ensures uniform quality, reduces on-site labor, and facilitates straightforward assembly—a perfect combination for a project that demands both speed and durability.

Interior and Finishing Works

While industrial facilities focus primarily on functionality, DTC doesn’t neglect aesthetics or employee comfort. The interior works include high-quality finishes that contribute to a safe, pleasant workspace. Floors are designed for slip-resistance and load-bearing capacity. Walls and ceilings incorporate insulation and fire-resistant materials as required, ensuring compliance with local building regulations.

Electrical and Plumbing Services round out the fit-out package, delivering consistent power and water supply to all areas of the factory. The result is a building that harmonizes heavy machinery with well-crafted, detail-oriented interior spaces for administrative and support staff.

Safety Equipment and Firefighting System Installation

One of DTC’s core philosophies is that a project’s success hinges on rigorous safety standards. Beyond code compliance, the Al Yamamah Steel Factory features:

- Specialized sensors to detect anomalies in temperature, pressure, or environmental conditions

- Clear emergency exits and signage designed to guide personnel quickly in crisis scenarios

- Regular safety drills supervised by DTC staff to ensure readiness

This comprehensive approach to safety not only protects the workforce but also preserves valuable equipment and inventory in the event of an emergency.

Why DTC Leads Factory Construction in Dammam

Industrial Construction Expertise

From steel factory construction to petrochemical facilities and beyond, DTC has demonstrated the ability to manage large-scale projects under tight deadlines. The Al Yamamah Steel Factory underscores their capability to integrate multiple complex systems—from power distribution and HVAC to advanced automation—while maintaining cost-efficiency and quality.

Advanced Infrastructure and Modern Design

DTC’s design philosophy embraces both functionality and aesthetics. The buildings aren’t just structurally sound; they also incorporate contemporary architectural elements. This blend of modern design and robust engineering helps factories adapt to evolving market demands and ensures a productive, enjoyable environment for employees.

Cutting-Edge Technology and Sustainability

The Al Yamamah Steel Factory is a testament to DTC’s commitment to eco-friendly practices, using technology that minimizes waste, optimizes resource consumption, and reduces the factory’s environmental footprint. As sustainability becomes a global priority, DTC remains at the forefront by recommending energy-efficient systems, using green materials, and following environmental guidelines.

Unwavering Commitment to Safety

In industries as high-stakes as steel manufacturing, a single oversight can lead to catastrophic outcomes. DTC’s rigorous approach to safety standards ensures that each project is delivered with robust firefighting systems, secure equipment installations, and well-planned emergency procedures.

Al Yamamah Steel Factory: A Cornerstone for Dammam’s Industrial Growth

This project not only enhances the industrial landscape of Dammam Industrial City but also sets a benchmark for future developments. With its state-of-the-art facilities and strategic location, the Al Yamamah Steel Factory promises to play a key role in advancing Saudi Arabia’s steel manufacturing sector. DTC’s comprehensive approach—spanning project conception, architectural design, engineering, and maintenance—makes it a prime candidate for businesses seeking to establish or expand industrial operations in the region.

How DTC Supports Your Next Industrial Venture

Whether you’re planning a new steel factory, refurbishing an existing facility, or developing an entirely different industrial complex, DTC offers:

- End-to-End Project Management: From site evaluation and feasibility studies to handover and post-completion support.

- Customizable Solutions: Tailored designs and engineering approaches that align with your production requirements, budget, and long-term vision.

- Local and International Expertise: Familiarity with Saudi regulations, plus global best practices in construction and sustainability.

- Ongoing Maintenance and Upgrades: As operations evolve, DTC stands by to assist with expansions, retrofitting, or technological enhancements.

By choosing DTC, you’re partnering with a factory construction company in Dammam that not only delivers on time but also takes pride in building structures that elevate your brand and operational capabilities. Each project is treated with the same level of dedication—from mid-sized specialized facilities to sprawling industrial complexes.

Conclusion

Al Yamamah Steel Factory is more than just an industrial site; it’s a showcase of DTC’s unwavering commitment to quality, innovation, and sustainability. As a leading factory construction company in Dammam, DTC leverages a wealth of experience, cutting-edge technology, and robust safety protocols to create facilities that empower businesses to thrive in Saudi Arabia’s competitive industrial landscape. If you’re considering a new factory project—be it steel-related, chemical, food processing, or beyond—DTC General Contracting is ready to transform your vision into reality.

Ready to elevate your industrial or commercial project to world-class standards? Partner with DTC General Contracting company in saudi arabia —the trusted name in factory and warehouse construction. Contact our expert team today to discuss your project requirements, explore tailored design solutions, and experience the difference that DTC’s dedication to quality, innovation, and safety can make for your business.

- Phone: +966 51 191 9056

- Email: info@dtc.sa

Transform your vision into a state-of-the-art facility that supports growth, efficiency, and long-term success. Reach out to DTC General Contracting now.