DTC Making PVC Membrane Roofing Efficient and Quick

Since the beginning of the 1960s, the PVC roof has been more popular for use on commercial, industrial, and institutional structures. Its endurance, capacity to endure extreme weather, and cost-effective installation and maintenance have all been credited as contributing to its rise in popularity.

In the event that your roof was recently damaged or is getting close to the end of its expected lifespan, having a PVC roof installation performed offers several advantages.

Types of Roofing PVC Membranes

PVC has been very popular for use in the construction of low-slope and flat roofs. The low cost of installation, the decreased load on structural parts, and the capacity to survive adverse weather were the primary factors that led to the proliferation of PVC roofing systems.

Standard PVC Membrane

The single-ply kind of PVC roofing membrane is the one that comes standard. PVC membrane roof materials are designed to provide long-term protection against water damage and heat reflection.

The typical composition of a PVC roofing system consists of two layers of membrane, with polyester placed in the center to serve as reinforcement. Additives make normal PVC more flexible, and the material may often be placed using either screws or adhesives.

PVC KEE Membrane

In the process of fabricating materials for PVC roof membranes, stiff components need to be adjusted in order to become more flexible. The liquid plasticizers that are utilized to make this process possible have the potential to evaporate over time.

In essence, a PVC KEE membrane helps a roof to keep its elasticity for a longer period of time and extends the expected lifespan of a roof. This category of PVC membrane roofing goods reflects the sun’s rays very well over time and may also be used in combination with asphalt.

Fleece Backed PVC Membrane

Additional support may be provided to a roof with a low slope or a level surface by fastening components of high-quality fleece to the bottom of a PVC membrane roofing product. The fact that fleece-inclusive materials may be rolled out directly on the roof makes the installation of these materials simpler.

This technology brings down the cost of labor while also producing an excellent protective PVC roofing layer.

Components of PVC Roofing System

A PVC roof is comprised of more than just a membrane alone. Every single installation of PVC roofing needs many layers of materials, each of which is intended to perform a distinct function.

The roof deck is a layer of hard material that is fastened to the structural supports of the building. It serves as a base for the other components of the PVC roofing system. A layer of insulation is normally installed on top of the roof deck for every PVC roof.

The thickness and kind are determined by the area weather patterns and how efficiently the energy is used.

A reliable connection between the membrane sheets and the roof deck may be achieved by using plates and fasteners in the appropriate locations. Depending on the weather and other considerations, using adhesives to install a PVC roof can prove to be the most effective method.

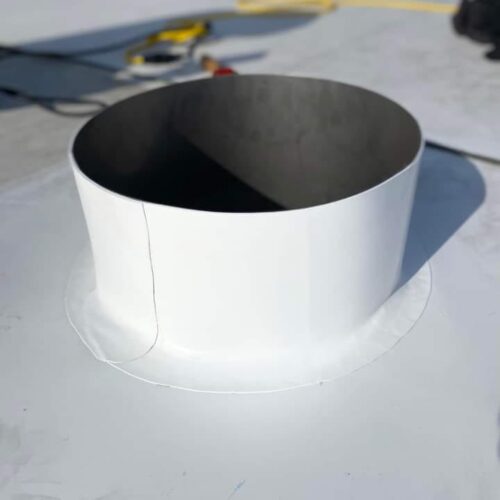

In regions that have a high frequency of windstorms, adhesives are sometimes a good option to consider. In addition, it is crucial to keep in mind that flashing and sealants are used in locations where a ventilation pipe, HVAC unit, or parapet goes through the roof.

Contact DTC For Expert Services

In order to ensure a high-quality installation of a PVC roof, experts such as at DTC are required to correctly flash and seal the area around the parapet to avoid water damage and moisture infiltration.

So, don’t wait any longer – and contact DTC for the best PVC membrane installation and advice.