The Ultimate Guide to Steel structure and industrial services and machine insslation and equipments in industrial projects contractor in saudi arabia

Overview of Industrial Contracting in Saudi Arabia

Saudi Arabia is expanding rapidly in manufacturing, oil and gas, renewable energy, petrochemicals, logistics, and construction. This growth has created a massive demand for steel structure solutions, heavy industrial services, equipment installation, and specialized contracting companies.

The keyword—steel strucuure and industrial services and machine insslation and equipments in industrial projects contractor in saudi arabia—represents a crucial segment in the Kingdom’s industrial landscape. These contractors play a vital role in building structural frameworks, installing machinery, managing equipment, and supporting complex industrial operations.

Under Vision 2030, the nation aims to localize manufacturing, expand industrial zones, and improve infrastructure. Industrial contractors are essential for executing these goals with world-class quality and safety.

Importance of Steel Structure Solutions

Steel structures offer durability, flexibility, and cost-efficiency, making them a primary choice for industrial facilities. Whether for warehouses, factories, or power plants, steel frames withstand harsh climates and heavy operational loads.

Contractors specializing in steel structure fabrication ensure precision engineering, corrosion protection, and compliance with Saudi regulations.

Rise of Heavy Industrial Services in the Kingdom

Industries such as oil & gas, cement, petrochemicals, and mining require heavy industrial services for smooth operations. These include:

-

Structural fabrication

-

Industrial maintenance

-

Heavy equipment installation

-

Electrical and mechanical works

-

Plant shutdown support

The demand continues to rise as Saudi Arabia expands its industrial zones like Jubail, Yanbu, Ras Al Khair, and NEOM.

Role of Steel Structure Contractors

Steel structure contractors manage all aspects of planning, fabricating, delivering, and assembling steel components. Their responsibilities include:

-

Material selection and procurement

-

CAD design and engineering

-

Welding, cutting, and fabrication

-

Sandblasting and painting

-

On-site erection and alignment

-

Final inspection and quality testing

Their expertise ensures strong, safe, and long-lasting structures for various industrial facilities.

Fabrication and Erection Processes

The fabrication process begins with detailed engineering drawings. Cutting and welding are performed with high precision using modern tools like CNC machines. Erection requires cranes, skilled riggers, and strict safety practices.

Each step must comply with international standards such as ISO 3834 and AWS D1.1.

Quality and Safety Standards in KSA

Saudi Arabia enforces strict regulations to maintain high safety levels. Contractors must follow:

-

SASO quality standards

-

Municipal safety codes

-

Ministry of Industry and Mineral Resources guidelines

-

ISO certifications

-

Aramco, SABIC, or Ma’aden specifications (when applicable)

Adherence ensures safe and reliable project execution.

Understanding Machine Insslation in Industrial Projects

Machine installation requires advanced engineering, accurate alignment, and deep technical knowledge. This includes placing, leveling, grouting, and connecting mechanical and electrical systems.

Machine insslation is crucial for the keyword steel strucuure and industrial services and machine insslation and equipments in industrial projects contractor in saudi arabia, as it determines plant performance.

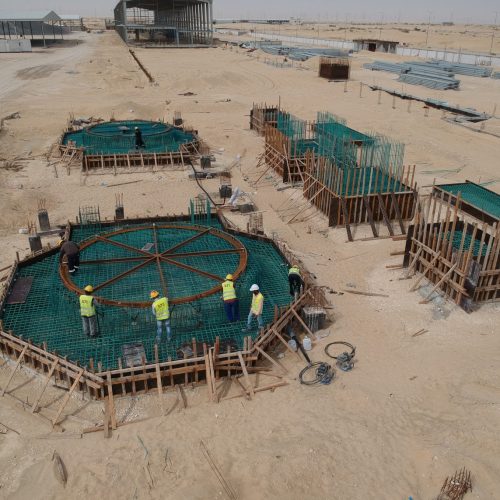

Pre-Installation Planning

Before installation begins, engineers perform:

-

Site surveys

-

Load calculations

-

Foundation studies

-

Equipment layout planning

-

Safety assessments

These ensure a smooth installation without delays.

Machine Alignment, Testing & Commissioning

After installation, the machinery undergoes vibration testing, electrical checks, and alignment verification. Commissioning ensures that all systems operate correctly before the plant becomes fully operational.

Equipments Handling in Large-Scale Industrial Sites

Handling heavy equipment requires expertise, special tools, and modern machinery. Contractors use:

-

Cranes

-

Forklifts

-

Skid loaders

-

Hydraulic jacks

-

Rigging tools

Proper handling prevents damage to equipment and ensures worker safety.

Lifting, Transport & Rigging

Major industrial sites rely on precise lifting and safe rigging practices. Contractors must comply with OSHA standards to avoid accidents.

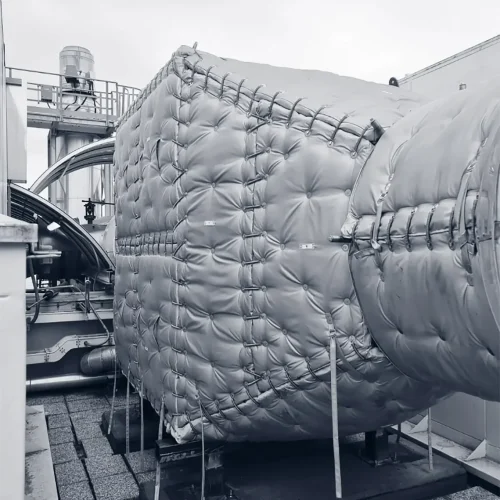

Preventive Maintenance of Industrial Equipments

Maintenance programs help avoid unexpected breakdowns. Services include:

-

Lubrication

-

Replacement of parts

-

Safety checks

-

Electrical diagnostics

Regular maintenance extends the lifespan of equipment and reduces downtime.

Why Hire a steel strucuure and industrial services and machine insslation and equipments in industrial projects contractor in saudi arabia

Hiring a specialized contractor ensures:

-

Compliance with Saudi standards

-

Access to certified technicians

-

Safe and efficient project execution

-

Expertise in complex industrial operations

Professional contractors bring hands-on experience with large industrial clients.

Compliance With Local Regulations

A good contractor understands all Saudi regulations and ensures proper documentation, inspection approvals, and permits.

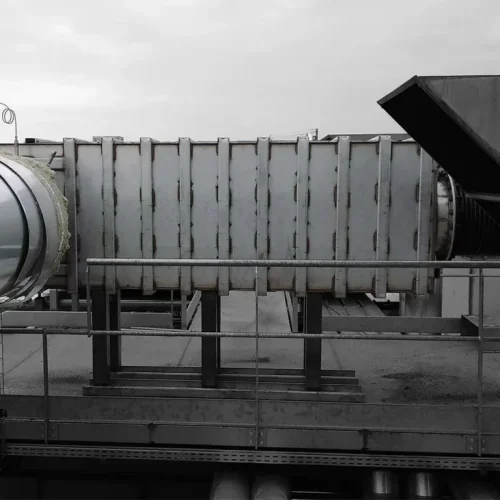

Expertise in Oil, Gas, and Petrochemical Facilities

These sectors require strict safety, high precision, and advanced engineering. Contractors in this field are experienced with refinery equipment, pipelines, and pressure vessels.

Choosing the Right Contractor in Saudi Arabia

Selecting the right contractor ensures project success and long-term reliability.

Checklist for Evaluating Contractors

-

Certifications and safety record

-

Completed projects

-

Skilled workforce

-

Tools and equipment availability

-

Compliance with Saudi regulations

-

Project management capability

-

Engineering expertise

-

Quality control procedures

-

Pricing transparency

-

Client reviews

Understanding Contracts & Project Timelines

Clear contracts help avoid disputes. They should include:

-

Scope of work

-

Timeline

-

Materials

-

Safety rules

-

Payment terms

Technologies Transforming Industrial Projects in KSA

Digital transformation is reshaping contracting.

Use of BIM and 3D Modeling in Steel Structure Projects

3D modeling helps detect clashes early and improves accuracy.

Automation in Machine Insslation & Equipment Handling

Robotic welding, automated alignment tools, and AI-based monitoring systems improve efficiency.

Cost Factors in Industrial Contracting

Budgeting includes labor, materials, transportation, cranes, testing, and permits.

Material Costs, Labor & Equipment Charges

Steel prices vary based on thickness, grade, and coating. Labor rates depend on skill level.

Hidden Costs to Watch For

-

Delayed permits

-

Extra safety measures

-

Additional testing

-

Weather impacts

Common Challenges in Industrial Projects & How to Avoid Them

Industrial projects often face engineering issues, delays, and safety challenges.

Engineering Errors & Delays

Proper planning and skilled teams reduce errors.

Safety Hazards & Regulatory Failures

Regular audits and training programs help prevent accidents.

FAQs

1. What does a steel structure contractor do?

They design, fabricate, and install steel frames used in industrial buildings.

2. Why is machine insslation important?

Proper installation ensures equipment operates safely and efficiently.

3. What sectors rely on industrial contractors in Saudi Arabia?

Oil, gas, petrochemical, power, food manufacturing, and logistics.

4. How do contractors ensure safety?

By following ISO, SASO, OSHA, and Saudi municipal standards.

5. What equipment is used in industrial projects?

Cranes, forklifts, hydraulic jacks, welding tools, and alignment devices.

6. How do I choose the best contractor in Saudi Arabia?

Check experience, certifications, completed projects, tools, and pricing.

External Link (Informational Reference)

Visit Saudi Arabia’s industrial development page for insights:

https://www.industry.gov.sa

The field of steel strucuure and industrial services and machine insslation and equipments in industrial projects contractor in saudi arabia is essential for building strong, safe, and efficient industrial environments. With Saudi Arabia’s industrial expansion, choosing the right contractor ensures high-quality results, compliance with regulations, and long-term reliability.