Design and Shop Drawing for Steel Structure: How DTC Delivers Build-Ready Clarity

Delivering on time and on budget starts with one fundamental asset: design and shop drawing for steel structure that is precise, coordinated, and build-ready. In Saudi Arabia—where industrial plants, malls, cold stores, and logistics hubs are fast-tracked—contractors, fabricators, and owners rely on drawings and models that remove guesswork, eliminate clashes, and optimize steel tonnage without compromising safety.

At DTC, we combine disciplined engineering with BIM-driven detailing to translate your design intent into fabrication-ready shop drawings, CNC deliverables, and erection sequences that shorten cycle times and reduce site risk across Riyadh, Jeddah, Dammam, and Al Khobar.

What’s Included: The Full Steel Shop Drawing Package

A comprehensive steel package goes far beyond pretty plans. It’s a set of documents and data that the workshop and site can trust.

General Arrangement (GA) & Layout Plans

-

Grid-based framing plans, column schedules, bay dimensions

-

Elevations and sections for vertical alignment and coordinate control

-

Anchor-bolt plans and base-plate setting details for civil teams

Connection & Component Detailing

-

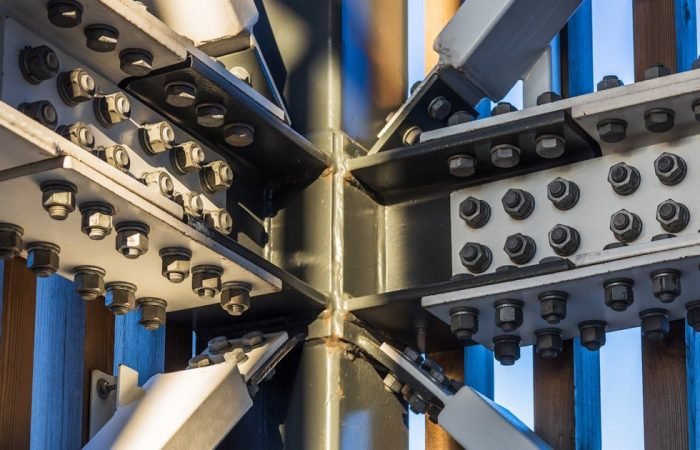

Moment, shear, bracing, and splice connections with bolt grades, diameters, slip-critical notes, and weld symbols

-

Stiffeners, seat angles, end plates, backing bars, and doubler plates as required by analysis

-

Fireproofing allowances, clearances, and coating break lines

Fabrication Drawings (Single-Part & Assembly)

-

Piece marks, cut lists, camber data, cope/notch geometry

-

Hole tables with tolerances, slot orientation, and punch/drill notes

-

Plate nesting optimization for minimal waste

Erection Drawings & Method Sequencing

-

Lift points, temporary bracing, splice heights, and bolt-up sequence

-

Tolerances per AISC Code of Standard Practice; survey/level benchmarks

-

Safe access and staging guidance to support the erection plan

Bills, Lists & Digital Deliverables

-

MTO/BOQ by grade/profile and bolt/weld schedules by location

-

DSTV/NC files for CNC drilling, coping, and plate processing lines

-

IFC exports for coordination with MEP, precast, and architectural trades

Codes, Standards, and Local Compliance

Our detailing aligns with SBC (Saudi Building Code) and international references such as AISC 360, AISC 341 (seismic), AWS D1.1 (welding), ASTM, and relevant Eurocodes where specified. We embed:

-

Design load combinations, deflection limits, and serviceability criteria

-

Coating and fireproofing notes consistent with Saudi Civil Defense approvals

-

Material callouts that match local supply (profiles, plates, fasteners)

Result: Drawings that sail through reviews and facilitate authority approvals.

BIM-Driven Coordination (Clash-Free by Design)

We produce and federate LOD 300–400 Tekla Structures/Revit models and run clash checks (with Navisworks/Trimble Connect) against:

-

Architectural façades and canopies

-

MEP/ELV risers, ducts, cable trays

-

Civil embeds, shear keys, curbs, and floor openings

Benefits you feel onsite

-

Fewer RFIs, fewer re-cuts, fewer site modifications

-

Clear interface packages: embed plate drawings, sleeve holes, and cast-in channels delivered on time

-

Predictable fabrication and erection sequences

Connection Design That Balances Strength, Cost, and Speed

Good connections are safe. Great connections are erectable, economical, and repeatable. Our engineers:

-

Select bolted vs. welded strategies per zone (shop-weld/site-bolt to minimize height-work)

-

Standardize plates, hole patterns, and bolt lengths across repetitive bays

-

Optimize splice locations (below crane limits, above obstruction, within tolerances)

-

Consider ductility and progressive collapse resistance where required

Fabrication Readiness: From Model to Machine

We design and title-block for the shop floor:

-

Clear piece marks linked across GA, assemblies, and singles

-

DSTV/NC outputs for beams, columns, and plates; DXF where applicable

-

Paint systems (blast class, DFT, intumescent zones), galvanizing notes, and touch-up details

-

Traceable revision control so the workshop always uses the current issue

Erection Intelligence: Safer, Faster, Smarter

Erection drawings are more than arrows and tags. We provide:

-

Sequence maps that balance stability and crane efficiency

-

Temporary bracing locations and release logic

-

Tolerance targets for plumb/level/square with survey checkpoints

-

Bolt-tensioning procedure notes (turn-of-nut, calibrated wrench, or DTI)

This level of clarity cuts hours from each lift and lowers rework risk.

QA/QC and Submittal Flow That Keeps You Moving

-

ITPs and checklists tied to hold-points (shop fit-up, weld inspection, bolt tensioning, coating DFT)

-

RFI tracking inside the model (clouded and indexed)

-

As-built updates reflecting site changes and final connection torque logs

DTC Project Examples Using This Approach

-

Kameyat Specialties Factory – Dammam

Design-build delivery with full BIM model, GA/connection detailing, and shop + erection drawings to support a fast-track industrial plant.

🔗 https://dtc.sa/portfolio/kameyat-factory-in-dammam/ -

Al Saif Cold Storage Warehouses – Dammam

14,000 m² temperature-controlled warehouse; detailing coordinated with insulation zones, vapor barriers, and overhead MEP for a clean, thermally reliable envelope.

🔗 https://dtc.sa/portfolio/al-saif-cold-storage-warehouses/ -

AMC Factory (Arabian Minerals & Chemicals) – Dammam

136,000 m² industrial facility; standardized splice details and repetitive bay connections accelerated fabrication and erection cycles.

🔗 https://dtc.sa/portfolio/arabian-minerals/ -

Tiypa (Tiba) Mall – Al Khobar

Long-span roof trusses and atrium framing; façade interface plates and canopy steel detailed to architectural tolerances.

🔗 https://dtc.sa/portfolio/tiypa-mall-alkhobar-ksa/ -

Bayfront – Al Khobar (Ajdan Bayfront)

Architectural steel for plazas and waterfront features; corrosion-protection schedules and stainless-steel fastener specs for the marine environment.

🔗 https://dtc.sa/portfolio/bayfront/

(Need more references? We can align the drawing index with Atyaf Avenue Mall, United Stars Warehouses, and Ajdan Infinity on request.)

What You Gain Working with DTC

-

Fewer surprises: Clash-free, sequenced deliverables that installers can trust

-

Speed: CNC-ready outputs and standardized details that compress fabrication time

-

Lower cost: Optimized tonnage, fewer non-standard parts, reduced rework

-

Approval confidence: Submittals aligned with SBC, AISC, AWS, and Civil Defense notes

-

Nationwide reach: Riyadh, Jeddah, Dammam, and Al Khobar support with on-site coordination

Frequently Overlooked—but Critical—Notes We Include

-

Movement allowances at expansion joints and thermal gaps

-

Fireproofing build-ups and leave-outs at connection zones

-

Roof step/valley steel and gutter support coordination with waterproofing

-

MEP hanger allowance strategy (avoid random drilling onsite)

-

Survey control: benchmarks, datums, and grid verification workflow

Call to Action

If your project needs design and shop drawing for steel structure that the workshop and site can build from—clean, coordinated, and compliant—let’s talk.

-

🌐 Website: dtc.sa

-

✉️ Email: info@dtc.sa -yousef.juhiash@dtc.sa

-

📞 Phone: +966 566 41 1325

-

📺 YouTube: https://www.youtube.com/@dtc.construction

-

💼 LinkedIn: https://www.linkedin.com/company/dtcsa/