Flue Gas Cleaning System & DeNOx SNCR Systems in Industrial Projects in Saudi Arabia – DTC General Contracting

Industrial growth in Saudi Arabia is accelerating like never before, fueled by mega-projects, Vision 2030 commitments, and rapid expansion in energy, petrochemical, and manufacturing sectors. With this growth comes an essential responsibility: managing industrial emissions through advanced flue gas cleaning system & DeNOx SNCR systems. DTC General Contracting has emerged as one of the leading EPC partners delivering these high-performance environmental solutions across the Kingdom.

This article explores everything you need to know—how the systems work, why they matter in Saudi Arabia, and how DTC plays a central role in elevating industrial sustainability.

Understanding Flue Gas Cleaning Systems in Modern Industries

A flue gas cleaning system is an engineered solution designed to remove harmful pollutants released from industrial combustion processes. These pollutants—NOx, SOx, particulate matter, heavy metals, and acidic gases—pose serious risks to public health, worker safety, and environmental quality.

Why These Systems Matter Today

Saudi Arabia is one of the world’s leading industrial economies, hosting:

-

Oil and gas refining plants

-

Petrochemical complexes

-

Power generation facilities

-

Cement and steel factories

-

Waste-to-energy projects

All these operations generate flue gases that must be cleaned effectively to meet environmental standards enforced by Saudi Aramco, the Royal Commission, and the National Center for Environmental Compliance (NCEC).

Key Pollutants Removed by Modern Systems

-

Sulfur Oxides (SOx)

-

Nitrogen Oxides (NOx)

-

Particulate Matter (PM10 and PM2.5)

-

Volatile Organic Compounds (VOCs)

-

Acidic gases (HCl, HF)

-

Heavy metals (Mercury, Lead, Cadmium)

By removing these pollutants, industries can significantly reduce their environmental footprint while protecting workers and nearby communities.

Types of Flue Gas Cleaning Technologies Used in Saudi Projects

Saudi Arabia implements multiple technologies depending on fuel type, industry sector, and environmental compliance requirements.

Dry, Semi-Dry, and Wet Scrubbing Methods

-

Dry Scrubbers: Inject dry sorbents (like lime) into the flue stream.

-

Semi-Dry Scrubbers: Use an evaporative approach to improve SOx removal.

-

Wet Scrubbers: Offer the highest removal efficiency for SOx, acidic gases, and fine particles.

Each method has advantages based on cost, space availability, and pollutant load.

Electrostatic Precipitators and Baghouse Filters

For particulate control, two systems dominate:

-

Electrostatic Precipitators (ESP) remove PM using electrical charges.

-

Fabric Filters (Baghouses) trap particles using high-efficiency filter bags.

These systems are crucial in cement factories and metal processing industries.

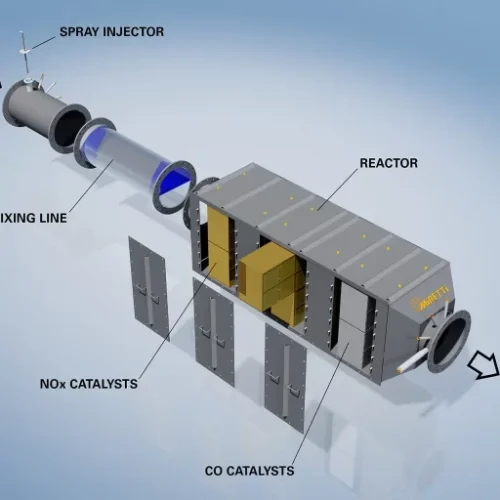

What Are DeNOx SNCR Systems?

Selective Non-Catalytic Reduction (SNCR) is a widely used technology for removing nitrogen oxides (NOx) from industrial flue gases.

SNCR works by injecting ammonia or urea directly into the furnace at high temperatures (850–1100°C). This triggers a chemical reaction transforming harmful NOx into harmless nitrogen and water vapor.

Chemical Reactions Involved in SNCR

For urea:

CO(NH₂)₂ + 2 NO + ½ O₂ → 2 N₂ + CO₂ + 2 H₂O

For ammonia:

4 NH₃ + 4 NO + O₂ → 4 N₂ + 6 H₂O

These reactions help industries cut NOx emissions by 40–70% without needing costly catalysts.

SNCR vs SCR – Key Differences

| Feature | SNCR | SCR |

|---|---|---|

| Catalyst Required | No | Yes |

| Temperature Range | High (850–1100°C) | Low (300–400°C) |

| Efficiency | 40–70% | 80–95% |

| Cost | Low | High |

| Maintenance | Minimal | Extensive |

SNCR is preferred for many Saudi industries due to its cost-effectiveness and suitability for large furnaces and kilns.

Role of DTC General Contracting in Saudi Industrial Emission Solutions

DTC General Contracting is a leading EPC company known for delivering large-scale industrial, mechanical, and environmental solutions across the Kingdom.

DTC’s Capabilities in EPC Industrial Projects

-

Full engineering design (mechanical, chemical, structural)

-

Procurement of high-grade materials and equipment

-

On-site construction and system integration

-

Installation, testing, and commissioning

-

Compliance documentation and certification

DTC ensures every project meets international emission standards such as EPA, EU Directive, and Saudi NCEC guidelines.

Why Top Industries Partner With DTC

-

Reliable project delivery

-

Strong technical expertise

-

Proven track record in heavy industrial installations

-

Ability to execute complex turnkey systems

-

Long-term maintenance and operational support

Applications of Flue Gas Cleaning & SNCR Systems in Saudi Arabia

Industries that Depend on These Systems

-

Cement plants

-

Petrochemical refineries

-

Steel and metal industries

-

Waste-to-energy plants

-

Power generation utilities

-

Desalination plants

These industries are expanding rapidly, creating large demand for advanced emission control technologies.

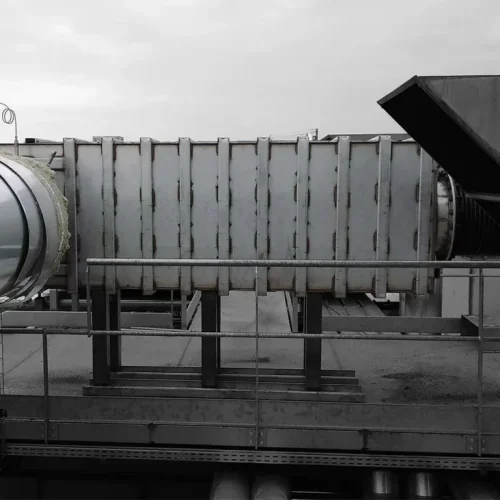

Technical Workflow of Installing a Flue Gas Cleaning System

DTC follows a structured process to ensure efficiency and compliance.

Engineering Design & System Sizing

-

Flue gas analysis

-

Computational fluid dynamics (CFD) modeling

-

Equipment sizing

-

Material selection

Material Procurement & Fabrication

-

Sorbent preparation units

-

Ducting and pressure vessels

-

Filters, scrubbers, injectors

-

Electrical and automation systems

Commissioning & Performance Testing

-

Mechanical completion

-

Start-up procedures

-

Calibration of injection systems

-

Final performance verification

Benefits of Implementing SNCR Systems in Saudi Industrial Sites

Operational Cost Savings

-

Low initial investment

-

No catalyst cost

-

Minimal downtime

Environmental & Health Advantages

-

Cleaner air

-

Reduced smog-causing NOx

-

Improved worker health

Challenges of Deploying Emission Control Systems in Harsh Environments

Saudi Arabia’s climate adds engineering challenges:

-

High ambient temperatures

-

Dusty conditions

-

Corrosive coastal environments

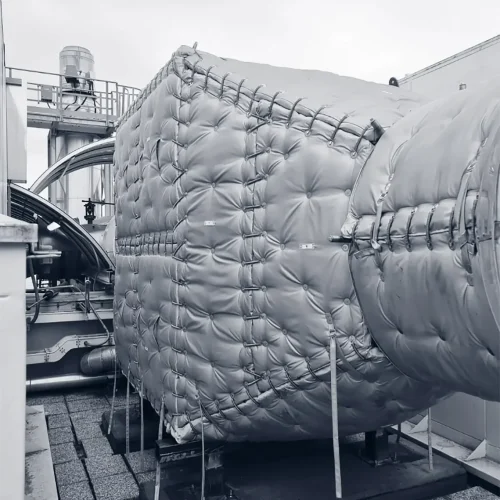

How DTC Overcomes These Challenges

-

Use of corrosion-resistant alloys

-

Sealed ducting systems

-

Advanced insulation

-

Continuous monitoring solutions

Future of Industrial Air Pollution Control in Saudi Arabia

With Vision 2030, Saudi Arabia is moving toward:

-

Greener industries

-

Hydrogen-based energy

-

Advanced digital monitoring

-

AI-supported emission controls

DTC is expected to remain at the forefront of these technological advancements.

FAQs

1. What is the main purpose of a flue gas cleaning system?

It removes harmful pollutants like SOx, NOx, particulates, and heavy metals from industrial exhaust gases.

2. How does an SNCR system work?

SNCR injects ammonia or urea into hot gas zones, converting NOx into nitrogen and water vapor.

3. Why are these systems important in Saudi Arabia?

They help industries meet strict national environmental standards and support Vision 2030 sustainability goals.

4. What industries need SNCR systems most?

Cement plants, power stations, petrochemical plants, and steel mills commonly use SNCR technology.

5. Does DTC General Contracting handle full EPC delivery?

Yes, DTC provides engineering, procurement, construction, commissioning, and maintenance services.

6. Where can I learn more about emission control technologies?

You may explore resources from the U.S. EPA or global industry publications.

External link: https://www.epa.gov

Conclusion

The integration of a flue gas cleaning system & DeNOx SNCR systems in industrial projects in Saudi Arabia – DTC General Contracting is essential for cleaner, safer, and more sustainable industrial development. As the Kingdom accelerates toward Vision 2030 goals, these technologies play a pivotal role in reducing industrial emissions, enhancing environmental protection, and supporting long-term economic growth.

DTC stands out as a trusted partner, delivering robust EPC solutions that empower industries to meet the highest environmental standards.