Why do we have to use steel fiber?

Steel fiber substantial deck can give better opposition than limit breaks in solidified concrete, as well as most extreme protection from enduring weighty burdens, either unique or static. On the off chance that you choose to use steel fiber substantial ground surface, you can choose to use a ‘joint-less floor’.

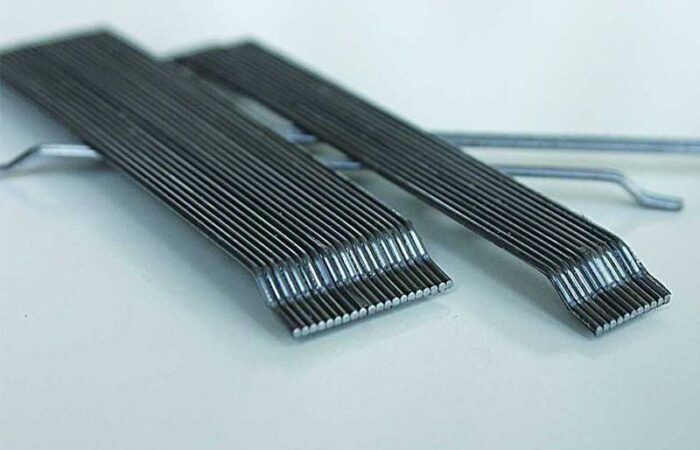

Steel Fibers for Construction

Materials for development use vary everywhere, and a considerable lot of the materials are obtained normally. Regular materials have been used for a really long time to construct structures, similar to homes. During the Egyptian period, normal filaments, for example, straw and horsehair were used to make mud blocks. Then, at that point, in the last part of the 1800s’, the US supported straw as one of the fundamental parts of wall bearing. Blocks are apparently one of the most involved materials for development in presence, urgent for public lodging because of their capacity to endure a variety of open-air components.

Concrete is another normal structure material, and fiber-built-up polymers have been added to substantial blends for more than fifty years. Adding strands to composite materials increments primary uprightness and guarantees they are more grounded, longer-enduring, and more impermeable.

Steel fiber technology for your projects

For a long time, steel fiber built-up concrete has fundamentally been used in non-underlying applications like modern decks and shotcrete. This is because of way that with conventional fiber measurement rates, steel fiber built up substantially shows a semi-malleable, strain-relaxing post-breaking conduct. Because of the advancement of new, better-performing strands, the extent of application for steel fiber-supported concrete has been altogether enlarged.

Steel fiber for Industrial Flooring

An accurately planned and built solid floor is the rudiment expected to create a useful and functional floor in the present modern structures. The right decision of steel fiber and significant particulars for floor pieces is of essential significance. Unacceptable floor pieces can bring about exorbitant healing cycles and possibly costly interruption of the client’s business.Forcetech long history of expertise in the field of steel fiber built-up deck applications empowers us to propose to every client the ground surface arrangement which gives the most advantages.

Reinforce Concrete

FORCETECH company provide the best steel fiber for construction project. Steel fiber-supported concrete is a composite material having strands as the extra fixings, scattered consistently at irregular in little rates, for example somewhere in the range of 0.3% and 2.5% by volume in plain concrete. SFRC items are made by adding steel strands to the elements of cement in the blender and by moving the green cement into molds. The item is then compacted and relieved by customary techniques.Balling is one of the issues experienced during mixing and compacting SFRC. This ought to have stayed away from the uniform appropriation of fibers. The energy expected for blending, conveying, putting, and completing SFRC is somewhat higher. The use of pan mixers and fiber gadgets to aid in better mixing and lessen the arrangement of fiber balls is fundamental.