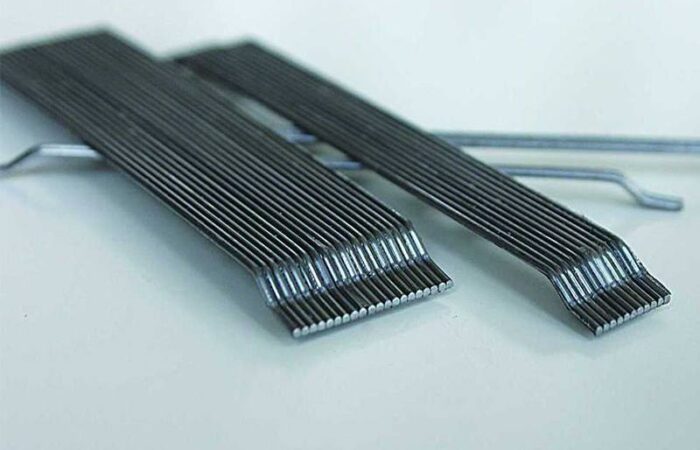

Glued Steel Fiber

Glued steel fibers are made of cold-drawn steel fibers that have been bent into hooked shapes and joined together to form bundles. They are produced by mechanically pulling low carbon steel wire rods repeatedly until the desired thickness is achieved. Then, the individual fibers are glued using water soluble adhesive to avoid fiber balls from developing (fibers bunching) during the concrete mixing process.

Glued Steel Fiber Advantages & Use

Forcetech FIBMIX can endure significant loads and survive deformation thanks to its high tensile strength. The hooked ends effectively transfer and distribute stress because they are secured in the concrete. Due to the structure’s small size and total encapsulation of the steel fibers by the alkaline concrete matrix, it is corrosion-resistant. Forcetech’s glued Steel Fiber has a substantially higher level of corrosion resistance than other types of reinforcing steel as a result.

Forcetech FIBMIX Compared to plain concrete, concrete reinforced with glued steel fibers is more efficient at absorbing and dissipating energy. As a result, Forcetech’s FIBMIX-treated concrete is ductile as opposed to untreated concrete’s brittleness. In addition, FIBMIX has a high flexural strength since the fibers must be extracted from the concrete matrix with a lot of force. In contrast to unreinforced concrete, which would completely disintegrate when it cracked (brittle behavior), Forcetech FIBMIX-reinforced concrete would continue to withstand weights even after it had fractured.

Under dynamic stress, Forcetech’s glued steel fiber concrete provides high impact resistance and performance. The improvement results from decreased stress concentration and enhanced fiber adhesion to matrix aggregates. There are 50% and 100% improvements in wearability and fatigue resistance compared to standard concrete without steel fibers.

Re-bar and mesh can be entirely or partially replaced with glued steel fibers in specific situations, saving money and accelerating construction. Steel fibers can be put into the container with other ingredients when mixing concrete. Compared to mesh and re-bars, which are heavier and need more work to fix and align, glued steel bars are simpler to add. Its excellent reinforcing capability makes it possible to reduce the slab thickness by 20%. This results in significant time and resource savings.

Glued Steel Fiber Application

- Slabs & Flooring: These products include flooring for industries, warehouses, residential buildings, porticos, airplane hangars, parking lots, and bridge decks.

- Precast: Examples of precast architectural and structural elements include rail sleepers, septic tanks, sewer pipes, cable ducts, prefabricated cabins, house walls, and rainwater collection systems.

- Shotcrete lines mines, tunnels, and canals to stabilize slopes in challenging terrain and fix structural problems in old buildings.

- Structures of strategic importance include safety vaults and strong rooms, military applications including anti-missile hangars and underground shelters, explosion-proof zones, seismically resistant buildings, nuclear containment shielding, and offshore construction projects.

Forcetech FIBMIX

Cold-drawn hooked ends steel fiber with high tensile strength is produced by a high-quality base low carbon steel bar in the production of FIBMIX Glued Steel Fiber. As a result, the reinforced fiber’s average tensile strength exceeds 1100MPa. As a result, stresses may be thoroughly diffused, and cracking propagation can be successfully controlled due to fibers’ high strength and uniform distribution. Refers to raw, loose-end, hooked fiber that has been glued together. The main distinction between glued and free fibers is that the free fibers is simple to disperse uniformly while the glued steel fiber is simple to block together.

| Description | |

| Diameter | 0.75 mm |

| Length | 60 mm |

| Aspect Ration | 80 |

| Tensile Strength | ≥1100 Mpa |

| Material | Low carbon steel bar- Coating: Non, Bright |

| Packaging | 25kg per bag |