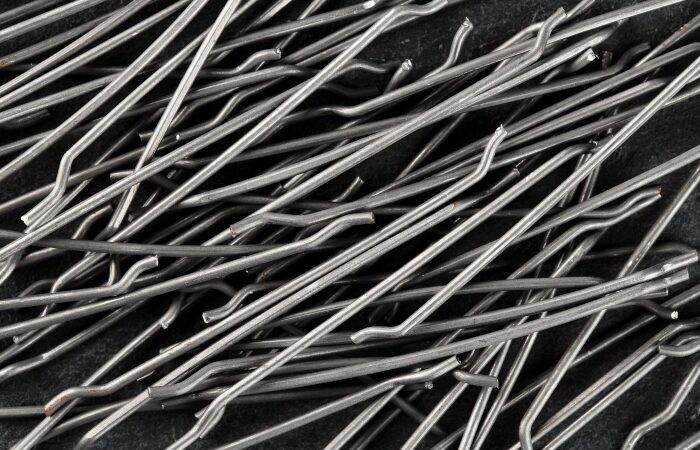

Loose Steel Fiber

The steel grids and the floor’s surface are both made of plain concrete, which is relatively brittle and prone to chipping and splitting. Forcetech steel fiber can effectively absorb energy, increase the concrete floor system’s impact resistance, and guard the floor system against damage. The performance of Forcetech’s loose steel fibers is greatly influenced by their shape, diameter, and length. Long and thin fibers have a higher capacity for anchoring, which improves their functionality. The fiber length ratio to diameter affects the performance of steel fibers and the concrete slab to which they are added.

The appropriate length-to-diameter ratio (aspect ratio) should result in improved performance. In actual use, however, the long loose fibers may ball up, preventing the dispersion of fibers during mixing concrete, which may affect how effectively it functions. As a result, there isn’t a single method for enhancing steel fiber performance. Instead, the requirements of the project dictate the aspect ratio.

Steel Fiber in Concrete

Forcetech’s steel fiber, a thin steel wire with a specific length and diameter, is added to concrete to improve performance. These randomly arranged steel fibers can successfully stop microcracks growth and macrocracks development in the concrete. Concrete’s tensile, flexural, fatigue, impact, and fatigue resistance are all markedly enhanced by steel fiber, as is its ductility. In addition, distinctive anchor ends can enhance the bond with concrete on both ends of the steel fiber. When the concrete deforms, the anchoring end effectively transfers and distributes the fiber, resolving the cracks into tiny, dispersed microcracks. A few examples of the uses for steel fiber include floors, railroads, tunnels, water conservation, power plants, subways, segments, airports, dams, bridges, docks, mines, metallurgy, minerals, industrial facilities, and civil constructions.

Loose Wire Hook-end Steel Fiber

Cold drawn loose wire hook-end steel fiber is a collection of loose wire that has been bound together with a water-soluble adhesive. For example, flooring, railroads, tunnels, power plants, subways, segments, airports, dikes, bridges, harbors, metallurgy, environmental protection, industrial facilities, and public structures are only a few applications for Forcetech’s loose hook-end steel fibers.

At the hook end of loose wire, there is more steel fiber. Consider the steel fiber, widely used in flooring projects, with a diameter of 0.75 mm and a length of 60 mm. It includes 4600 fibers per kilogram, and when 1.5 kg of concrete is applied to each square meter, it amounts to 69,000 fibers. If the floor is 200mm thick, there will be 13,800 steel fibers per square meter of the floor. The extraordinarily high distribution density of steel fibers, which also has total control over fracture breadth, significantly impacts the dispersion of floor cracks. This cannot be supported by steel bars.

Economic Advantages of Hook-end Steel Fiber

Forcetech’s steel fiber at the hook end can conserve concrete while maintaining strength. Manufacturers of concrete fiber can use their hook-end steel fiber to totally or partially replace steel bars. Construction can be completed more quickly when Forcetech’s hook-end steel fiber is used, and it is especially suitable for larger projects that require rapid and continuous concrete irrigation.

Hook-end steel fiber and conventional concrete are mixed and constructed similarly without additional tools. As a result, products made of hook-end steel fiber offer greater performance, a longer lifespan, and notable social benefits.

Forcetech FIBMIX

Quality foundation low carbon steel bar has outstanding mechanical qualities and high tensile strength and is used to create cold-drawn hooked steel fiber. As a result, the reinforced fiber’s average tensile strength exceeds 1100MPa. As a result, stresses may be thoroughly diffused, and cracking propagation can be successfully controlled due to the fibers’ high strength and uniform distribution.

| Description | |

| Diameter | 0.6 to 1.05 mm |

| Length | 60 mm |

| Aspect Ration | ≥50 |

| Tensile Strength | ≥1100 Mpa |

| Material | Low carbon steel bar-Non coating, Bright |

| Packaging | 25kg per bag |