Application of Reinforced Concrete Mix

Forcetech is the pioneer in providing reinforced concrete mix with their state-of-the-art product FIBMIX. The proper type of concrete is essential for whatever project you’re working on. Understanding the various types of concrete is particularly helpful since the concrete mix you choose will significantly affect the project’s success, whether it is a household build or a large-scale project. Although the essential ingredients of all concrete mixtures are the same—cement, water, and a mix of sand and stone—several other elements can be added to change the final properties of the concrete. Do you want to know more? Continue reading.

Application of Concrete

Concrete is a key component of urban infrastructure, from large skyscrapers in major cities to interstate roads. So, finding concrete somewhere should not be surprising given that it is the world’s most often used manmade material.

Before starting any concrete work, the appropriate type of concrete must be selected. For example, reinforced concrete is suitable for structural elements like columns and beams that require high tensile strength. On the other hand, lightweight concrete is recommended when creating light concrete blocks for residential buildings. Concrete is a material with many uses and is very adaptable. Concrete is the ideal base material for building structures, urban infrastructure, and a range of precast objects due to its flexible yet robust properties.

Application of Glass Fiber Reinforced Concrete (GFRC)

GFRC is typically used as an outside façade or cladding material for new construction and the rehabilitation or recladding of existing building faces. Additional applications include repairing and replacing terra cotta, fireplace surrounds, concrete surfaces, faux rocks, and planters. Another example is ornamentation found in architecture, such as cornices, window and door surround, and column covers.

Plastic Fiber Reinforced Concrete

Concrete’s essential ingredients are all created naturally. But concrete’s properties can be changed by merely adding some plastic fiber. Although concrete has several advantageous characteristics, such as good compressive strength, durability, specific gravity, and fire resistance, it may be overlooked because of its low tensile strength. However, the tensile qualities of the concrete can be improved by adding plastic fiber.

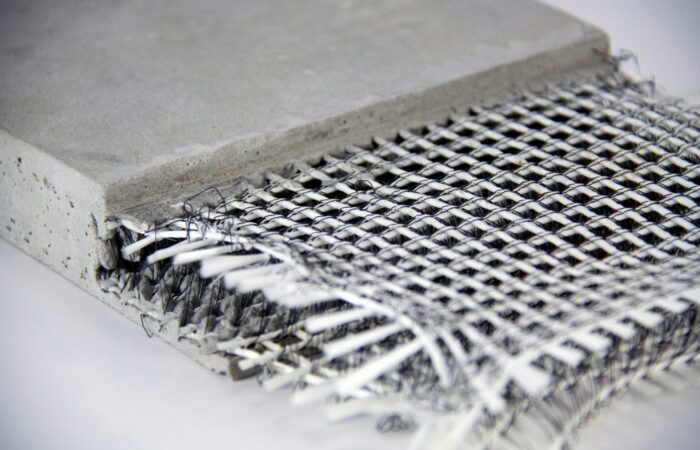

Carbon Fiber Reinforced Concrete (CFRP)

The maintenance and enhancement of infrastructure, including buildings and bridges, is a broad topic covered by the CFRP. Fresh concrete reinforced with CFRP reinforcing bars can completely prevent corrosion issues and significantly boost a member’s structural strength. The lifespan of constructions may be greatly extended with the use of carbon fiber-reinforced polymer, reducing the requirement for maintenance. Additionally, ablative polymers and lightweight, incredibly rigid, and robust constructions have been reinforced with carbon fibers.

Steel Fiber Reinforced Concrete (SFRC)

Forcetech’s steel fiber reinforced concrete is an affordable alternative for the uncracked section design of concrete members. Using Forcetech’s steel fiber reinforcement in concrete improves the structural elements’ resistance to high pressures. Concrete specifically reinforced with Forcetech’s steel fibers is utilized as extra material to decrease the possibility of cracking, improve resistance to impact or dynamic stress, and prevent material disintegration.

Forcetech Solutions

Worried about acquiring the best solution for your concrete needs? We have got your back! Forcetech is one of the most innovative companies with the aim of delivering a superior product (FIBMIX) that takes users’ needs and experience to the another level. These powerful phrases represent unshakeable principles to which we will always be devoted. We at FORCETECH never stop working toward attaining our goal. We are always motivated to set and overcome challenging targets to increase our position in the industry.