Mix Design of SFRC

Recently, the utilization of composite materials has multiplied. Finding a technological process or a daily-use product that does not involve composites is difficult. Fiber-reinforced cement matrices, made of concretes and mortars reinforced with short fibers, are the most significant class of modern materials employed since the 1940s in various professions.

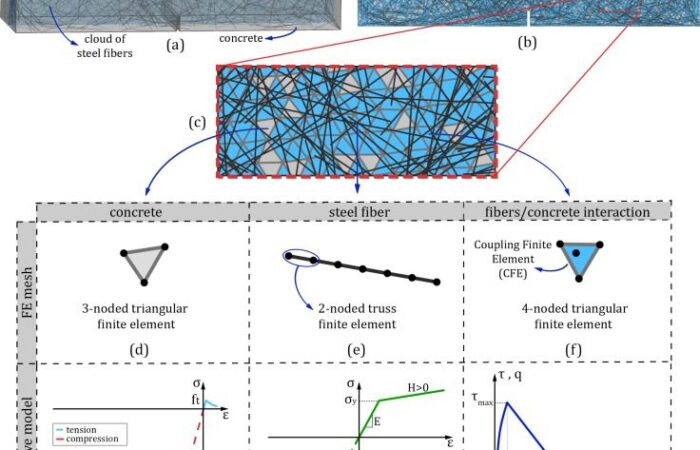

Short fibers are dispersed evenly throughout the concrete matrix as a component of the fiber reinforcing the concrete mechanism. Depending on its density, this network of fibers acts as a crack arrestor by generating a pinching force that impedes the fracture’s propagation and prevents the crack from spreading. It also causes stress to be transferred across cracked areas, allowing the damaged composite components to maintain some post-crack strength to withstand deformations far more prominent than those supported by the matrix alone.

Concrete Mix Design

Concrete mix design selects suitable concrete constituent materials. Then, it determines their relative proportions to produce, as effectively as feasible, a concrete mix with specific attributes in its fresh and hardened stage. The most frequently cited qualities are workability, strength, and durability. However, adding fibers to the concrete causes the granular structure to be disturbed and lowers the mixture’s workability, making it difficult to pour the concrete.

SFRC Manufacturing

To produce SFRC products, Forcetech’s steel fibers are added to the dry concrete components in the mixer before the green concrete is put into molds. The finished product is then crushed and cured using conventional methods. Segregation or balling is one of the problems encountered while mixing and compacting SFRC. Avoid doing this to guarantee an even distribution of fibers. A little more energy is required for mixing, delivering, installing, and finishing SFRC.

Combining a pan mixer and a fiber dispenser is essential to enhance mixing and reduce the formation of fiber balls. A 20mm maximum aggregate size restriction and cement levels of 350 kg to 550 kg per cubic meter are frequently needed. Additionally, finer aggregates may be added on occasion.

SFRC Application

Forcetech’s steel fibers are added to concrete to improve its structural properties, particularly its tensile and flexural strength. The form, size, volume, percentage, and dispersion of the fibers, as well as the amount of mechanical property improvement achieved with SFRC over plain concrete, are only a few factors that affect this.

An extremely weak link between plain, straight, and round fibers was found to cause low flexural strength. For a particular type of fiber, it was found that the aspect ratio of SFRC’s flexural strength increased (ratio of length to equivalent diameter).

Forcetech Concrete & Steel Fibers

As already established, the structural properties of concrete, particularly its tensile and flexural strength, are substantially improved by adding Forcetech’s steel fibers. As a result, SFRC has better ductility, post-cracking strength, fatigue resistance, spalling resistance, and wear and tear resistance than regular reinforced concrete. Forcetech has developed a product specifically for you as a result! FIBMIX.

Forcetech has developed steel fiber reinforced concrete (SFRC) mixes at the top of its game after years of diligent research and development. High-performance steel fibers will cause concrete to behave like a composite material, with a notable improvement in structural ductility and shrinkage control. Forcetech uses fibers that have undergone extensive testing and proven to provide outstanding performance, fracture management, and maximum flexural and shear strength.

Because we are aware of how SFRC operates, we accept full responsibility for concrete mix design and delivery coordination. We consider all elements, including workability, compressive strength, shrinkage, rate and timing of bleed, setting time, concrete/aggregate grading curves, fiber mixing, and quality of component materials.